Project Announcement – Kamloops STP – Hydro International’s Advanced Grit Management System

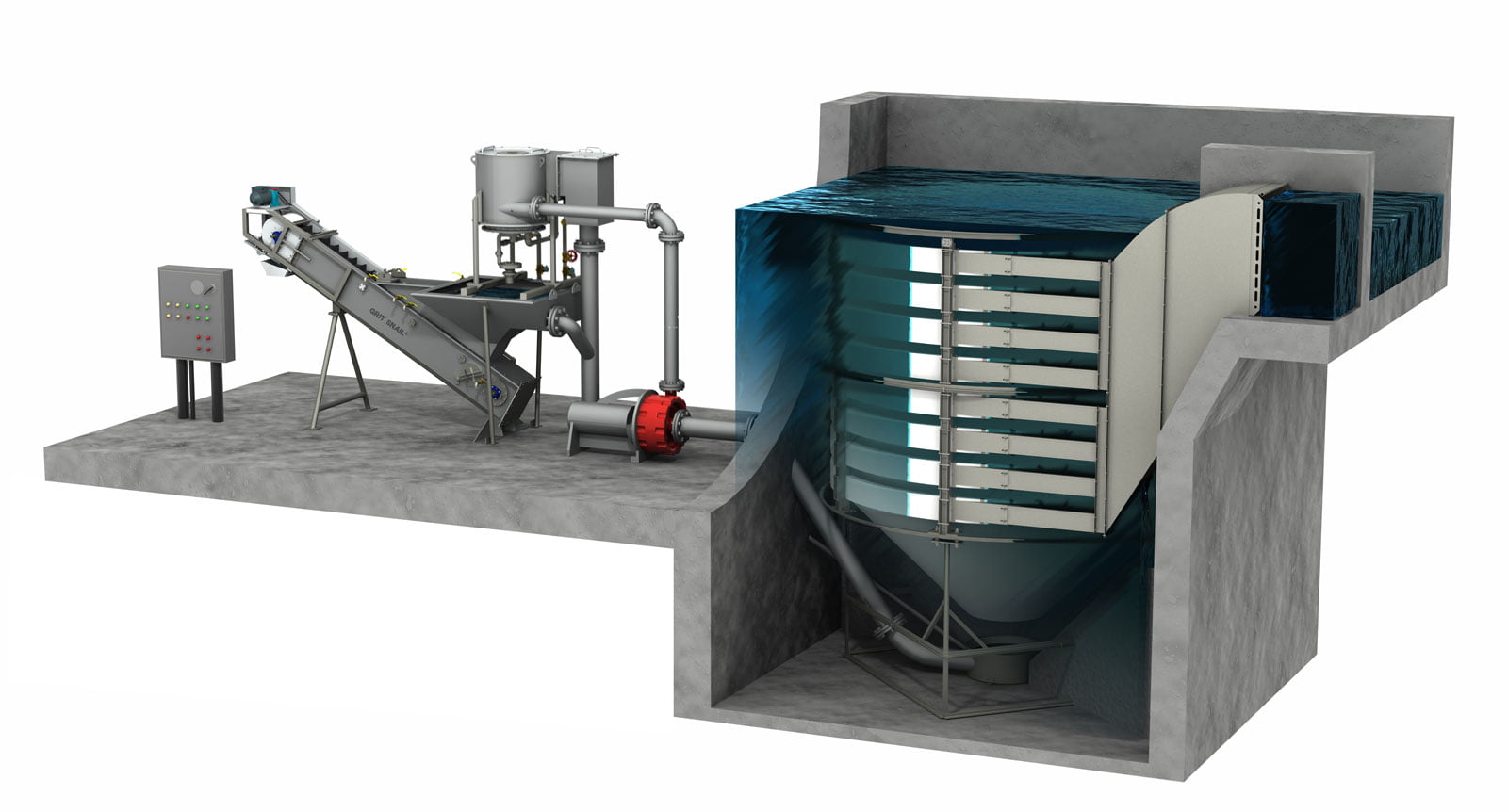

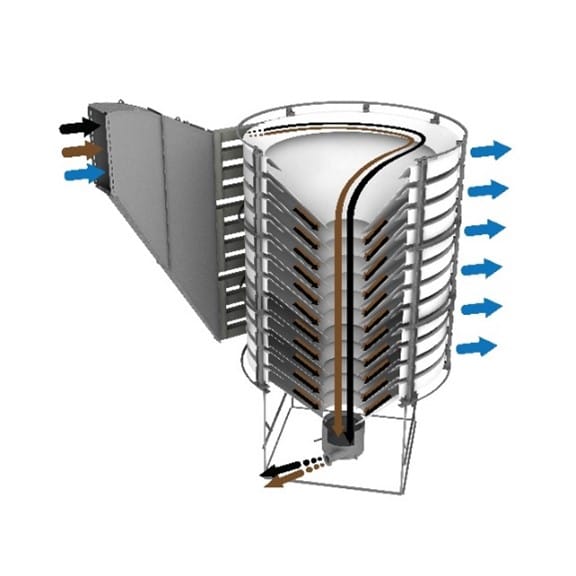

We are pleased to share that Hydro International has been awarded the contract to supply two (2) 12 ft diameter HeadCell® stacked tray grit separators as well as two OpTeaCup® grit classifier and GritSnail® grit dewatering units for the Kamloops Sewage Treatment Plant (STP). The HeadCell® grit separators give Kamloops STP the ability to reliably capture grit and remove it from the wastewater stream before it makes its way to downstream processes. Coupling the HeadCells® with the OpTeaCup® and GritSnail® units provides the plant with an Advanced Grit Management System and the ability to produce a clean, dry grit that can easily be handled and disposed of.

The most recent major headworks upgrade to the Kamloops STP achieved substantial completion in 2014. Since then, the Plant’s existing grit removal system has not performed as expected resulting in uncaptured grit being carried over to downstream processes. Some of the consequences of grit carryover are reduction in process tank volumes, mechanical abrasion and wear to rotating equipment resulting in increased O&M costs. Implementing the innovative HeadCell® along with OpTeaCups® and GritSnail® system will:

- Minimize unnecessary wear to downstream mechanical equipment.

- Minimize deposits and accumulations in process tanks.

- Help produce a clean & dry grit to be hauled away to landfills. The dryer the grit the less the plant will pay in hauling fees.

HeadCell® – Advanced Grit Management

OpTeaCup® & GritSnail®

HeadCell® Stack Tray

OpTeaCup® & GritSnail®

With the grit challenges facing the Kamloops STP, the HeadCell® stacked tray units along with OpTeaCup® and GritSnail® units were evaluated and selected by the City to move forward with implementation. The Advanced Grit Management System offers numerous advantages over traditional technologies, namely:

- Best in class capture efficiency and performance backed by independent third-party testing. Guaranteed to capture 95% of all grit 75 micron and larger at the design flow rate.

- No moving parts in the basin and thus no external power required.

- Stacked tray design makes it ideal for retrofits since it has a low footprint relative to other technologies. In many applications, existing structures can be used to significantly reduce overall project costs by reducing concrete and construction costs.

- Can be sized to handle a wide range of flows with less than a foot of headloss.

- OpTeaCup® outputs less than 20% Volatile Solids when sufficient fixed solids are present in the wastewater influent.

- GritSnail® is capable of output of 60% Totals Solids and less than 15% Volatile Solids when paired with the OpTeaCup®.

This is the first Advanced Grit Management System from Hydro International to be implemented at a large wastewater plant in the BC Interior and will join the ranks of over twenty Hydro International systems installed throughout Western Canada. Given the tight permit requirements coupled with plants running advanced biological processes in the region (BNR, Membranes, etc.), it’s important to evaluate and implement a technology that can stack up to the challenges municipalities face with respect to grit intrusion into treatment plants. By implementing a tested and reliable Advanced Grit Management System, municipalities can better protect their investments in plant infrastructure. We are grateful and excited for the opportunity to work with the City and their engineer/contractor to deliver a successful project.

Leave A Comment